RADIATION STERILIZATION PLANT OF MEDICAL DEVICES AND ALLOGRAFTS

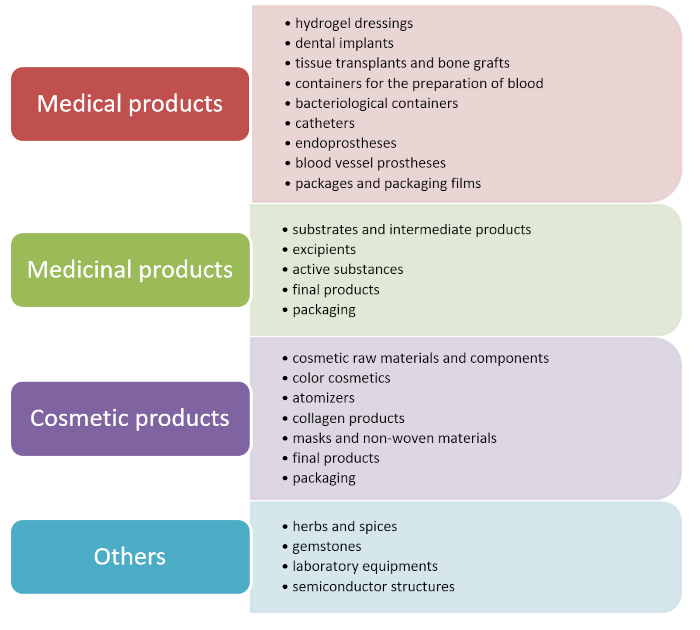

This accelerator is based on a travelling wave accelerating section. 10 MeV electron energy and 10 kW average beam power are applied for radiation processing. SSR carries out service activities in the field of sterilization and radiation hygienization, guaranteeing the delivery of a absorbed dose previously agreed with the Customer. The conducted process is validated in accordance with the requirements of PN-EN ISO 11137-1:2015-07/A2:2020-03 Sterilization of products used in health care - Radiation - Part 1: Requirements for the development, validation and routine control of a sterilization process for medical devices.

Since 2007, the Radiation Sterilization Station for Medical Devices and Allografts has a certified Quality Management System based on the PN-EN ISO 13485:2016-04/A11:2022-01 standard for the design and performing of sterilization process for medical devices.

The SSR has also a manufacturing authorisation for human medicinal products, issued by the Chief Pharmaceutical Inspector, in the field of sterilization of active substances, excipients and final product with the use of an electron beam. The process is carried out taking into account the principles of the Good Manufacturing Practice, GMP, which has been confirmed by the certificate of GMP compliance of a manufacturer.

Advantages of radiation sterilization:

- high efficiency of inactivation of microorganisms in the entire volume of the bulk package,

- short sterilization time,

- room temperature of the process,

- products after sterilization do not require quarantine,

- the possibility of sterilization of materials in unit and the collective package to prevent secondary contamination,

- no toxic residues in the sterilized material,

- the possibility of sterilization of products containing closed spaces,

- possibility of modification of material properties.

Requirements for the packaging of products delivered for sterilization:

- maximum dimensions of package cannot exceed 46 x 58 x 20 (cm) and their gross weight cannot exceed 6.0 kg. The maximum area density cannot exceed 2.5 g/cm2. If smaller packages are used, their weight should be proportionally lower, the formula for the calculation below:

package weight [g] = 2.5 × package length [cm] × package width [cm]

- the unit products should evenly fill the collective package in its entire volume (if it is not, they should be protected from moving in the package),

- the unit products should be packed in a package that provides an appropriate sterile barrier system (the package should be made of ionizing-resistant material),

- the quantity and manner of packing of the products in the collective package must be consistent with a pre-prepared loading pattern to ensure delivery of the acquired dose in the entire volume of the collective package,

- any changes to the material, shape of the product and the manner of packing must be absolutely reported before irradiation, as they may result in failure to deliver the acquired dose in the entire volume of the package.

Determining of the sterilization dose

One of the elements necessary to carry out the radiation sterilization process is to determine the sterilization dose, which defines the minimum dose of radiation that should be used to achieve the assumed level of sterility (SAL). Detailed information on determining the sterilization dose is included in the PN-EN ISO 11137-2:2015-08/A1:2023-09 standard.

Irradiation order Irradiation is carried out on the basis of an order delivered to each batch of products. The order should contain the following data:

- Customer's data (including company name, contact details and tax identification number),

- the exact name of the product with the batch number,

- quantity of cardboards/collective packages,

- dose and method of irradiation (one-sided or two-sided),

- date and signature.

Dose Delivery Certificate

Upon receipt of each batch of products, the Customer receives a written confirmation of the delivered dose of ionizing radiation (the Certificate of irradiation with electron beam and the Report of the day on the average values of accelerator parameters during the irradiation of a given batch of product). After irradiation, the boxes/cardboards are attached with barcode labels, confirming that the process has been correctly carried out. There are also used visual dosimetry indicators that change the color after irradiation.

The price of irradiation depends on the radiation dose. The time of irradiation are agreed individually with the Customers, depending on the quantity of the delivered cardboards/bulk packs.

Istitute of Nuclear Chemistry and Technology

Radiation Sterilization Plant of Medical Devices and Allografts (SSR)

ul. Dorodna 16

03-195 Warszawa

| Tel: | + 48 500 221 819 |

| + 48 22 504 13 38 | |

| + 48 22 504 12 25 | |

| Fax: | +48 22 504 1313 |

m.rzepna@ichtj.waw.pl